Home / Upgrades

The C2S design offices and technical teams (either mechanical or automation/control) are available to study any improvement, aiming to maintain performances and restore productivity of all production lines by implementing up-to-date technologies.

Give a new life to your wire and cable equipment!

More than 1 600 successful operations have been realised since 2010.

"C2S upgrades success is the result of our customized approach, and, before all, the success of a team 100% concentrated on customer support! Upgrading or Rebuild can be an excellent choice for wire and cable actors to meet their challenges”.

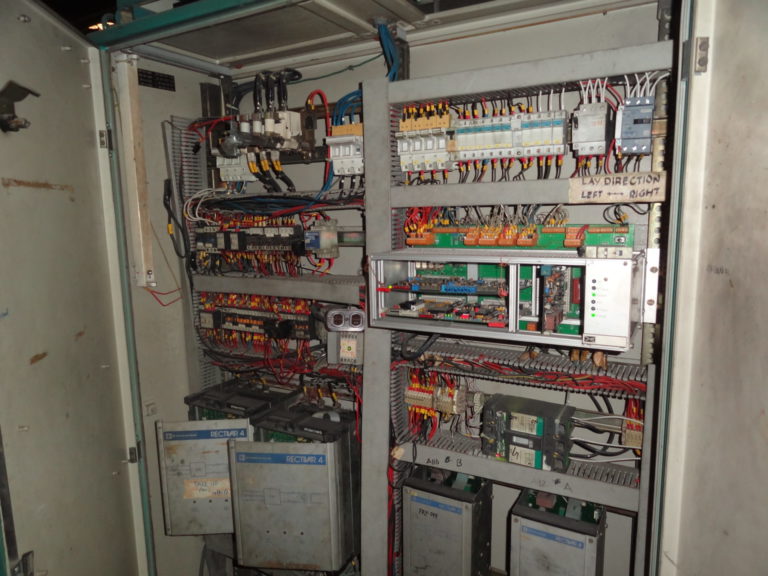

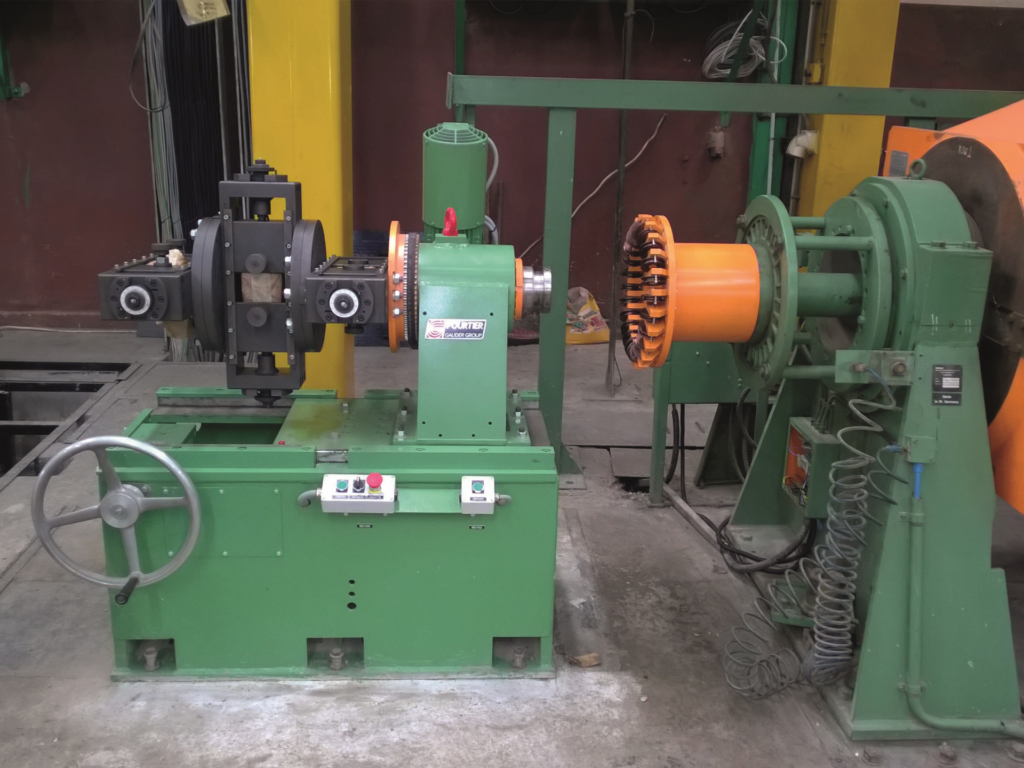

Replace old mechanical systems by electrical shaft, special PLC, drives, electrical cabinet, loading system, sound proof cabinet…

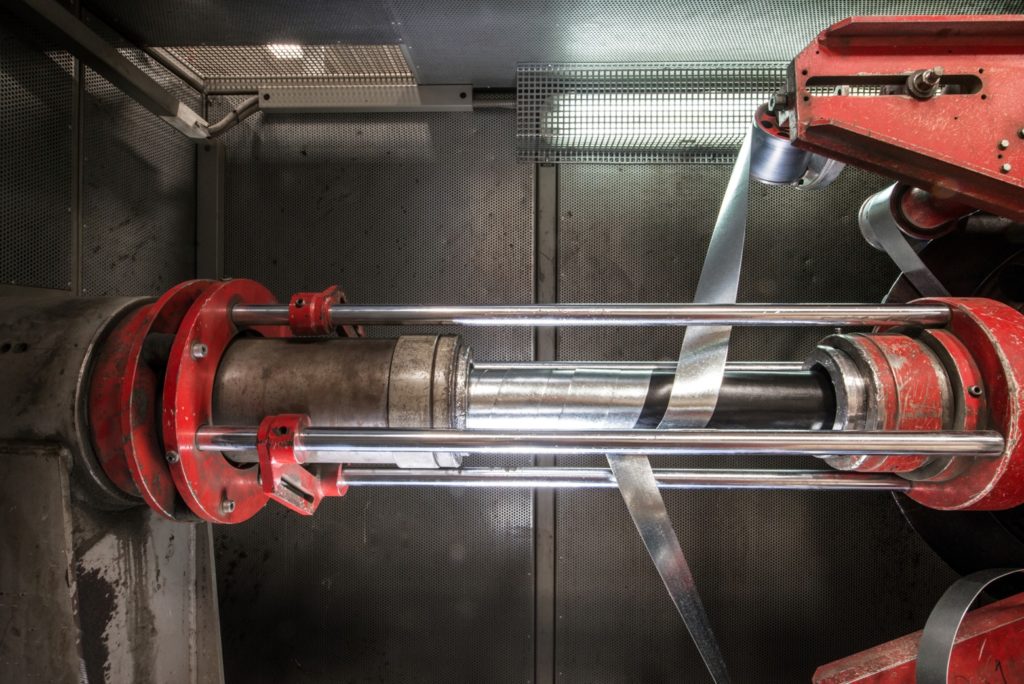

Existing signal rings can be replaced by bluetooth system on Double Twist machines to save maintenance time and reduce brushes consumption.

We can study and offer upgrades for a variety of process equipment components, no matter what brand of equipment you have.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |